What to Know Before Purchasing Metal Roofing Supplies

- Aaron Williams

- Sep 29

- 5 min read

Complete Metal Roofing Supplies Guide – Panels, Flashing & Materials

Aaron Williams

September 30, 2025

Planning a metal roof installation? Whether you're a contractor preparing for your next project or a homeowner working with your builder, understanding metal roofing terminology and component options will help ensure you get the right materials for a successful, long-lasting installation. At Indaco Metals, we've been helping Oklahoma builders and homeowners navigate these decisions since 1995.

Understanding Metal Roofing Panel Types

The first major decision you'll face is choosing between standing seam and exposed fastener systems. Each has distinct advantages depending on your project requirements, budget, and aesthetic preferences.

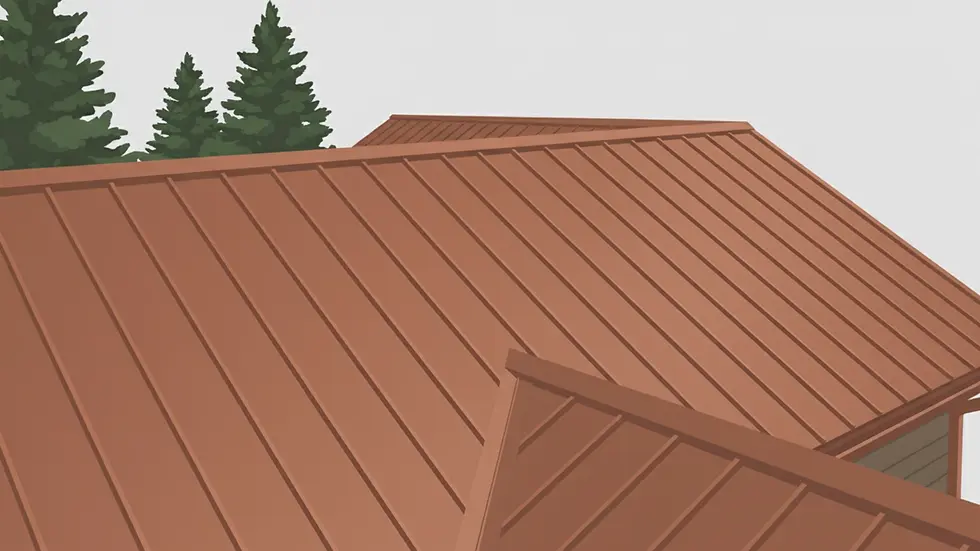

Standing Seam Metal Roofing

Standing seam systems feature panels that connect with raised seams, hiding all fasteners beneath the panel edges. This creates a clean, continuous appearance across the roof surface while providing superior weather protection. The hidden fastener system eliminates potential leak points and allows for thermal expansion without compromising the roof's integrity.

Standing seam roofing typically costs more upfront but offers enhanced durability and weather resistance. The system works particularly well for low-slope applications and provides excellent protection against Oklahoma's severe weather conditions. Installation requires specialized tools and techniques, making professional installation often necessary.

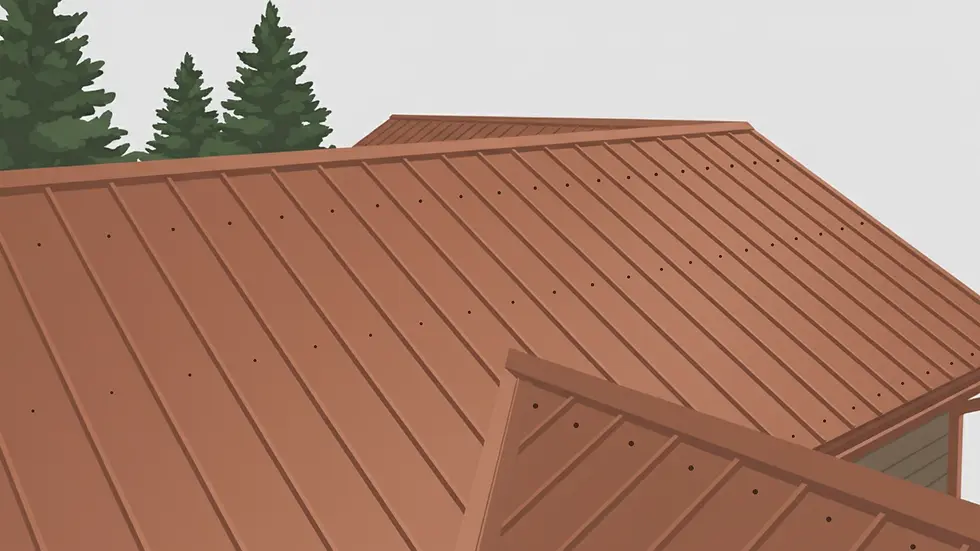

Exposed Fastener Metal Roofing

Exposed fastener systems attach panels directly through the metal to the roof deck using visible screws with rubber washers. This traditional approach offers a more economical option while still providing excellent durability and weather protection when properly installed.

Our DuraLoc and R-Panel profiles represent quality exposed fastener options that have proven reliable across thousands of Oklahoma installations. These systems install more quickly than standing seam and work well for steeper roof pitches where water runoff is rapid.

Essential Flashing Components

Proper flashing installation determines whether your metal roof performs as designed or becomes a source of water intrusion problems. Understanding the different flashing types helps ensure your material order includes everything needed for a complete installation.

Step Flashing

Step flashing protects the intersection where your roof meets vertical walls, chimneys, or dormers. These L-shaped pieces install in a stepped pattern, with each piece overlapping the one below it. Quality step flashing prevents water from penetrating these vulnerable transition areas.

Valley Flashing

Valley flashing channels water where two roof planes meet at an inside angle. This critical component must handle concentrated water flow, making proper material selection and installation techniques essential. Open valley systems use visible flashing, while closed valleys hide the flashing beneath the roofing panels.

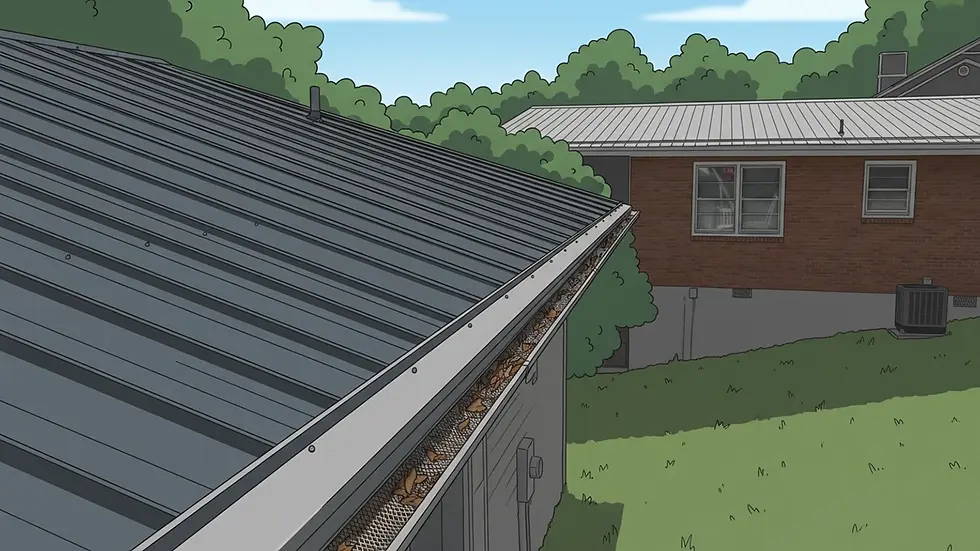

Drip Edge Flashing

Drip edge flashing protects the roof's perimeter by directing water away from the fascia board and into the gutter system. This seemingly simple component prevents costly moisture damage to your roof's structural elements and should be included in every metal roofing project.

Ridge Cap and Hip Flashing

Ridge cap covers the peak of your roof where panels from opposite slopes meet. Hip flashing serves a similar function where roof planes meet at an outside angle. Both components require proper ventilation considerations to prevent moisture accumulation in the attic space.

Underlayment Systems Explained

Metal roofing underlayment provides a secondary weather barrier and helps prevent ice dam damage during extreme weather conditions. Choosing the right underlayment depends on your climate, roof pitch, and local building code requirements.

Underlayment Type | Cost | Durability | Weather Resistance | Best Applications |

Traditional Felt | Lowest | Good | Basic protection | Standard applications, budget projects |

Synthetic | Medium | Excellent | Superior tear resistance, UV protection | Most metal roof projects, extended exposure |

Self-Adhering | Highest | Excellent | Waterproof seal, ice dam protection | Valleys, eaves, premium installations |

Traditional Felt Underlayment remains a cost-effective option for many applications. While less durable than synthetic alternatives, quality felt paper provides adequate protection when properly installed according to manufacturer specifications.

Synthetic Underlayment offers superior tear resistance and weather protection compared to traditional felt paper. These materials resist UV exposure during installation delays and provide better walkability for installers. Synthetic options typically cost more but offer enhanced performance characteristics.

Self-Adhering Underlayment creates a waterproof seal around fasteners and provides excellent protection in vulnerable areas like valleys and eaves. This premium option works particularly well in ice dam-prone regions and provides added insurance against water intrusion.

Material Compatibility Considerations

Not all metal roofing components work well together. Understanding material compatibility prevents galvanic corrosion and ensures your roof system performs as designed throughout its intended lifespan.

Fastener Compatibility

Use fasteners specifically designed for your panel type and substrate material. Stainless steel or galvanized fasteners prevent corrosion issues that can develop when dissimilar metals contact each other in the presence of moisture.

Sealant Selection

Choose sealants and tapes that remain flexible throughout temperature cycles and maintain adhesion to your specific panel materials. Incompatible sealants can fail prematurely, creating leak points that compromise your roof's performance.

Trim and Accessory Materials

Ensure all trim pieces, gutters, and accessories use compatible materials and finishes. Mixing different metal types can create galvanic corrosion that leads to premature failure of roof components.

Planning Your Material Order

Accurate material takeoffs prevent project delays and ensure you have everything needed for completion. Consider these factors when planning your order:

Panel Quantities

Calculate panel requirements based on actual roof measurements, adding appropriate waste factors for cuts and overlaps. Factor in ridge lengths, hip measurements, and valley requirements when determining total panel needs.

Fastener Requirements

Fastener quantities depend on panel width, roof area, and local wind load requirements. Order appropriate fastener types for different roof areas, including specialized fasteners for ridge and edge conditions.

Accessory Items

Don't forget essential accessories like pipe boots, vent flashings, and snow guards. These small components often get overlooked but are crucial for a complete, weather-tight installation.

Getting Expert Guidance

With nearly 30 years of experience serving Oklahoma builders and homeowners, our team understands the specific challenges and requirements of metal roofing in our climate. We're here to help you select the right materials for your project and ensure you have everything needed for a successful installation.

Whether you're planning a complete metal roof replacement or need specific components for a repair project, our knowledgeable staff can guide you through the selection process. We stock quality materials from trusted manufacturers and understand how different products perform in Oklahoma's challenging climate.

Ready to Start Your Metal Roofing Project?

Don't let confusion about materials and terminology delay your project. Our experienced team is ready to help you understand your options and select the right components for your specific application.

Contact us today for expert guidance:

Shawnee Location:

3 American Way

Shawnee, OK 74804

(405) 273-9200

Sand Springs Location:

17427 W 9th St

Sand Springs, OK 74063

(918) 419-6053

Hours: Monday - Friday, 8 AM - 5 PM

Visit either location to see our materials firsthand and discuss your project requirements with our experienced team. With the right materials and proper planning, your metal roof will provide decades of reliable protection for your Oklahoma property.